ArcelorMittal Tubular Products Altensteig introduces its first Product Carbon Footprint study for Welded Precision Steel Tubes

ArcelorMittal Tubular Products Altensteig has conducted a Product Carbon Footprint (PCF) audit for precision steel pipes. Providing evidence based on a uniform standard contributes to more transparency in the market and enables customers to significantly reduce their Scope 3 emissions.

When it comes to the CO₂ footprint of processes and products, apples are often compared to pears. The reason being: different methodologies or underlying data, which are often only partially comparable, lead to results that do not provide a transparent and meaningful picture. The Steel Pipe Industry Association, of which ArcelorMittal Tubular Products Altensteig is a member, aims to address this issue and has therefore launched the association initiative "Reducing Carbon Emissions from Tubes & Pipes – On the way to CO₂-neutral steel pipes". The goal is to develop strategies, concepts, and measures to achieve legally required climate neutrality.

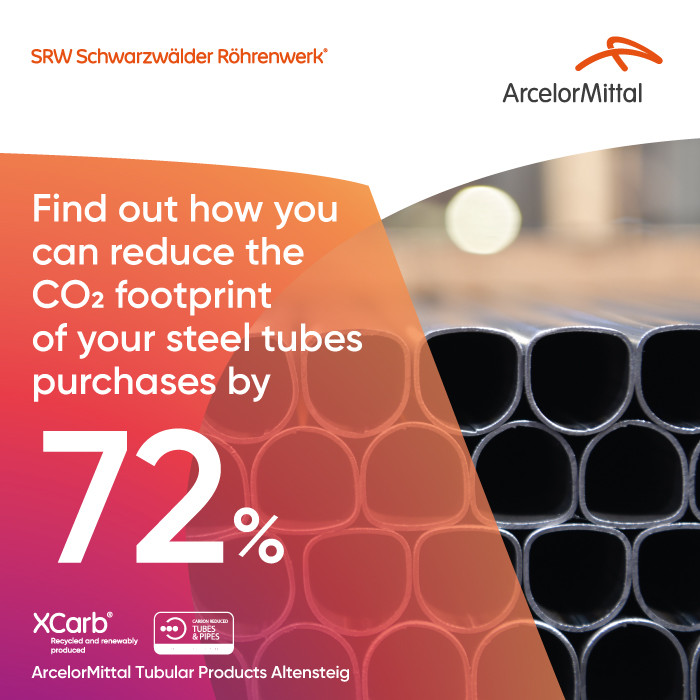

One of the measures is the creation of Product Carbon Footprints (PCF) for various steel pipe products of different product categories. ArcelorMittal Tubular Products Altensteig has also had two products, used for example in the furniture industry, store fitting, heat exchangers, or scaffolding, tested for their CO₂ footprint: on the one hand, pipes made with standard steel from the blast furnace route, and on the other hand, the innovative XCarb® pipes, which consist of low-carbon, recycled, and renewable XCarb® hot-rolled steel coils. They originate from ArcelorMittal's plant in Sestao, Spain, and are produced there in an electric arc furnace (EAF) using at least 75 percent scrap and 100 percent renewable electricity. The results of the audit are remarkable: XCarb® pipes show a 72 percent reduction in CO₂ emissions compared to pipes made from standard steel.

"This milestone we have achieved with XCarb® demonstrates our commitment to taking responsibility and ecological leadership in the steel industry," emphasizes Adrian Alecu, Managing Director of ArcelorMittal Tubular Products Altensteig. Through the transparency and comparability of the carbon footprint, ArcelorMittal Europe – Tubular Products provides a more sustainable option for its customers by helping them significantly reduce their Scope 3 emissions. Scope 3 encompasses all other indirect emissions generated in a company's value chain. "At the same time, the PCF contributes to a more sustainable, carbon-neutral future for the production of steel pipes," Alecu is convinced.

For the implementation of the audit according to the Greenhouse Gas Protocol and the standard DIN EN ISO 14067, the partner Green Navigation is responsible for all members of the Steel Pipe Industry Association.